Malgré les avantages évidents des pinces à tubes octogonales, quels défis se posent lors des processus de pré-assemblage et de re-mesure ?

Les tubes octogonaux ont une forme uniforme et, lors de l'assemblage, le positionnement du connecteur dépend du positionnement des trous calculé manuellement. Ce processus manuel peut entra?ner un mauvais alignement des trous, empêchant une bonne prise et une manipulation précise de la pièce.

La séquence dans laquelle les vis sont serrées peut provoquer de légères rotations incontr?lables entre les tubes connectés, affectant la capacité de la pince à maintenir un alignement précis et une bonne adhérence sur les pièces.

Pour les pièces de plus grande taille (par exemple, les panneaux latéraux automobiles), la pince peut dépasser 2 mètres de longueur. Lors des mouvements du robot et des ajustements d'angle, la gravité peut provoquer des déformations, affectant la précision de la préhension.

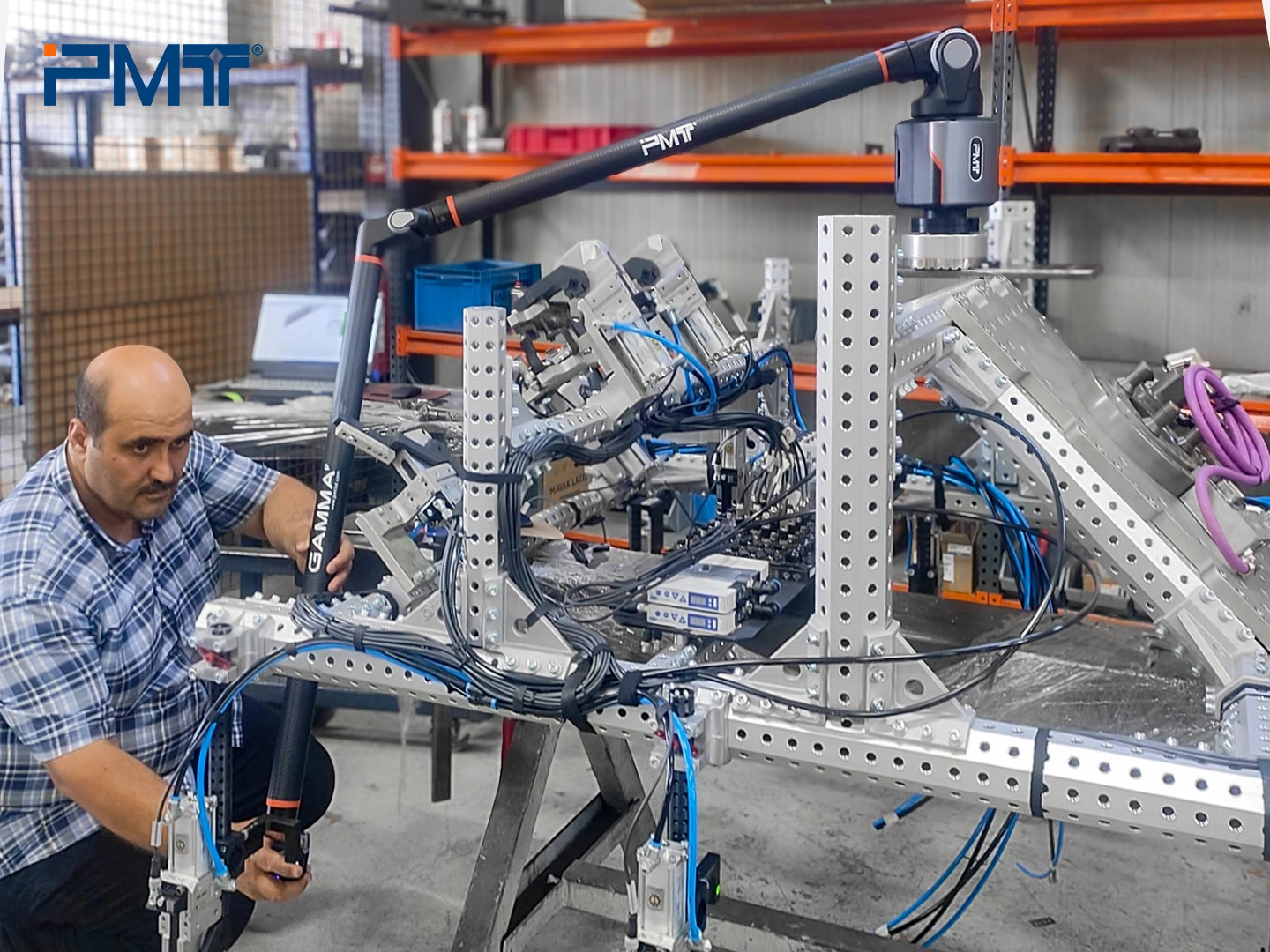

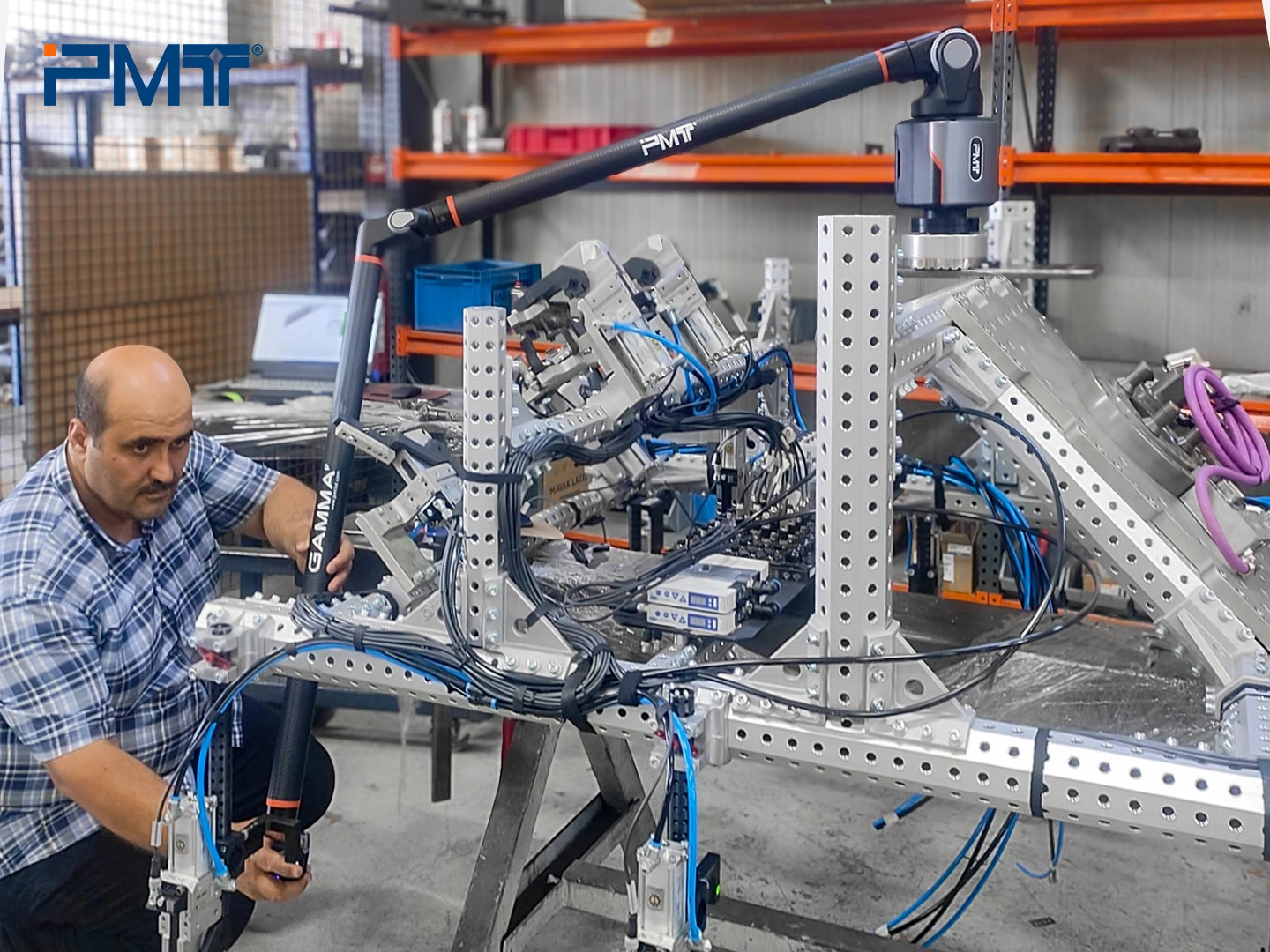

Pour relever les défis mentionnés ci-dessus, le bras de mesure portable offre une solution idéale, alliant portabilité et haute efficacité pour les processus d'assemblage et d'inspection des pinces à tubes octogonaux. Cette étude de cas illustre comment un important fournisseur turc de solutions d'automatisation a utilisé le bras de mesure portable PMT pour résoudre des problèmes de production critiques, améliorant ainsi la précision et l'efficacité de son processus de fabrication.

Le bras de mesure PMT permet de contr?ler en temps réel la concentricité et la perpendicularité entre la pince et la bride du robot, ainsi que le parallélisme et la perpendicularité entre les tubes. Cela permet de détecter et de prévenir les défaillances dues à l'accumulation d'erreurs.

En alignant les trous d'épingle sur la plaque de connexion avec le modèle CAO, les trous mal alignés dans l'assemblage peuvent être rapidement détectés et corrigés, garantissant une réponse rapide et maintenant la précision de l'assemblage.

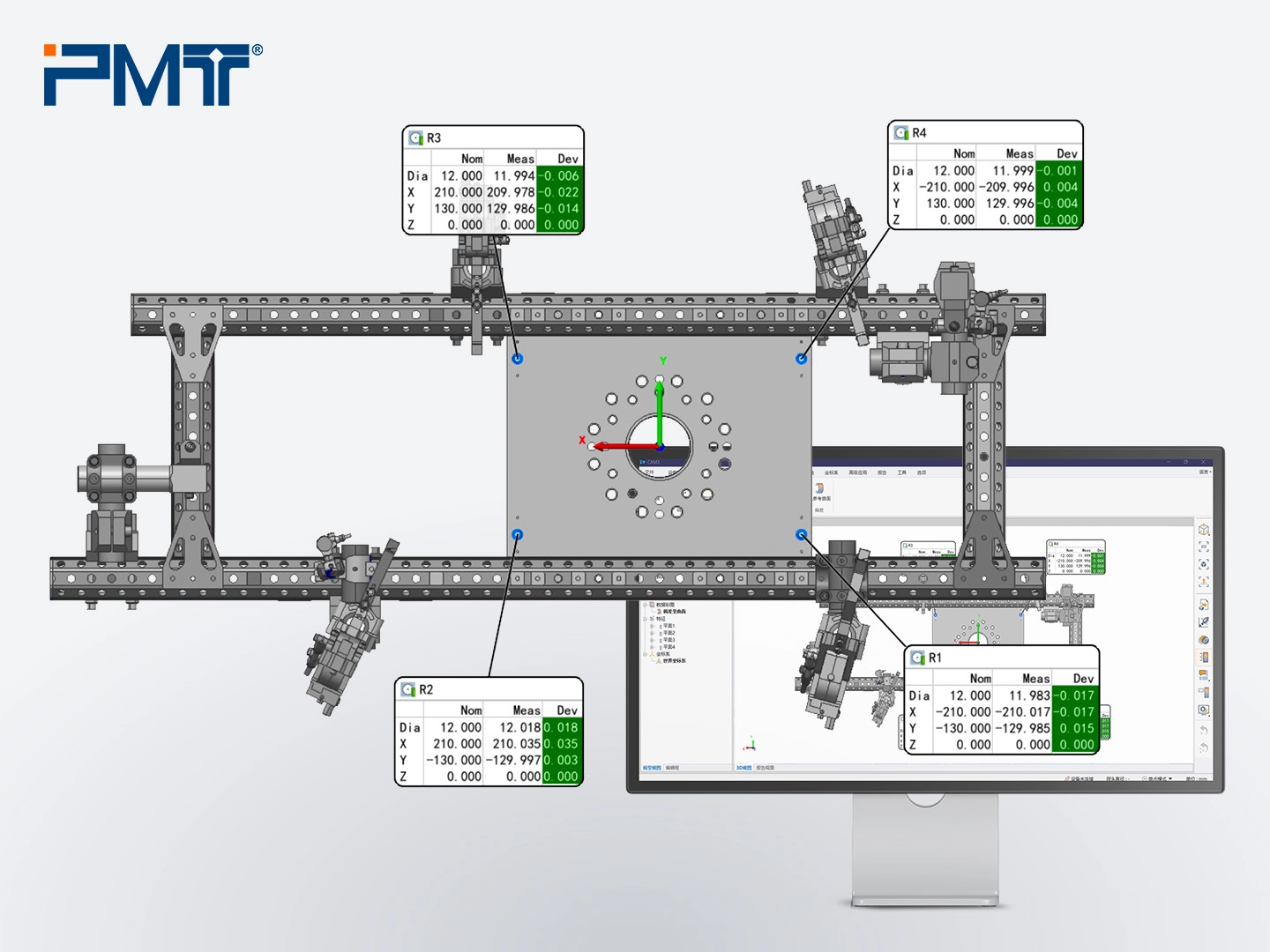

1. Utilisez la sonde du bras de mesure portable pour entrer en contact avec les trous de référence sur la plaque de connexion, puis appliquez Best-Fit pour aligner la pince avec le modèle CAO dans le logiciel de mesure 3D.

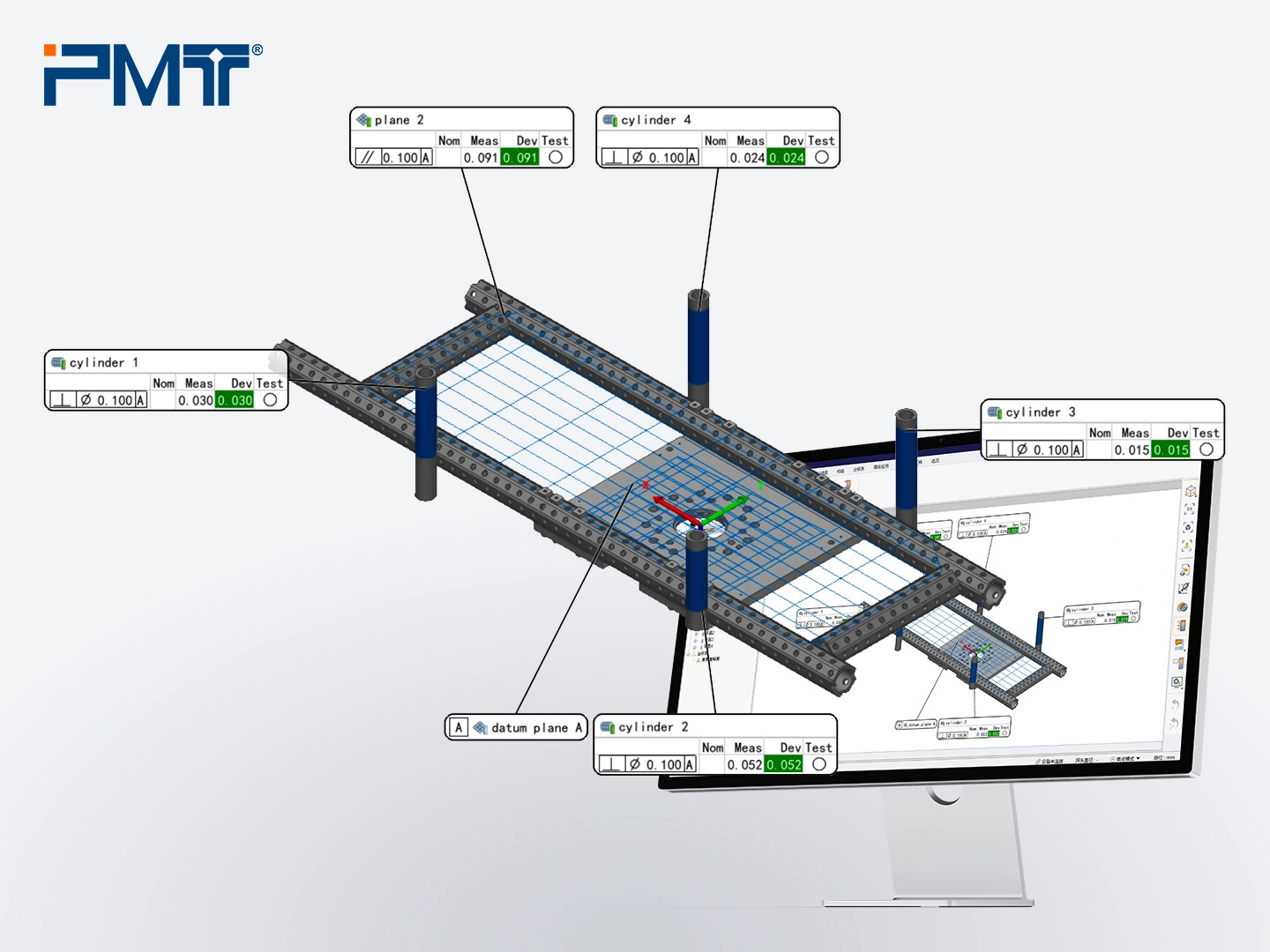

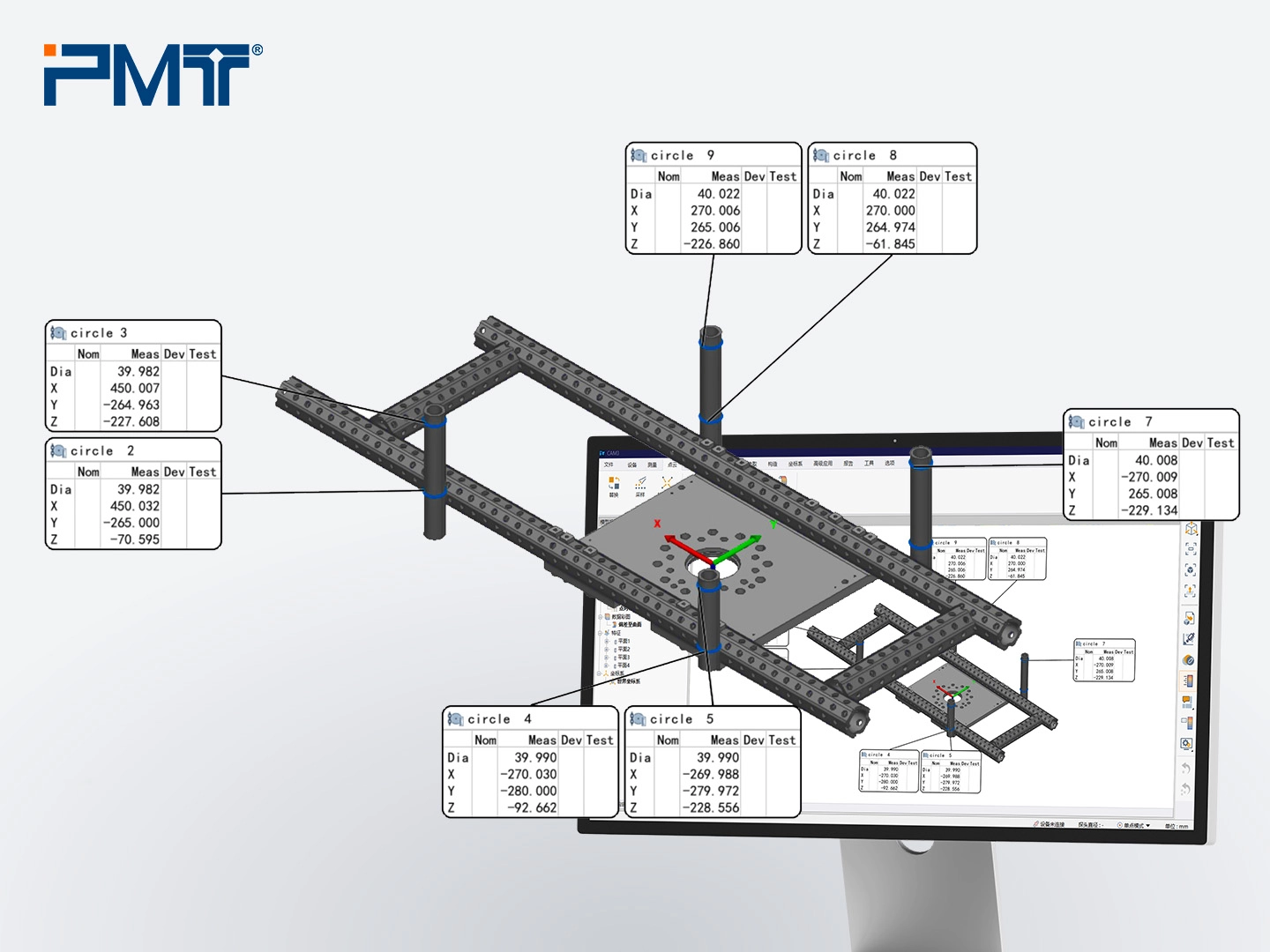

2. Mesurez le plan de la plaque de connexion et définissez-le comme référence A. Mesurez ensuite le plan du cadre principal et les tubes verticaux cylindriques des autres pinces pour évaluer le parallélisme et la perpendicularité.

3. Si les écarts dépassent la tolérance, construisez des éléments (par exemple, des cercles sur des tubes cylindriques) et comparez les coordonnées XY à différentes hauteurs pour calculer les ajustements nécessaires. Cette étape garantit la précision de l'assemblage.

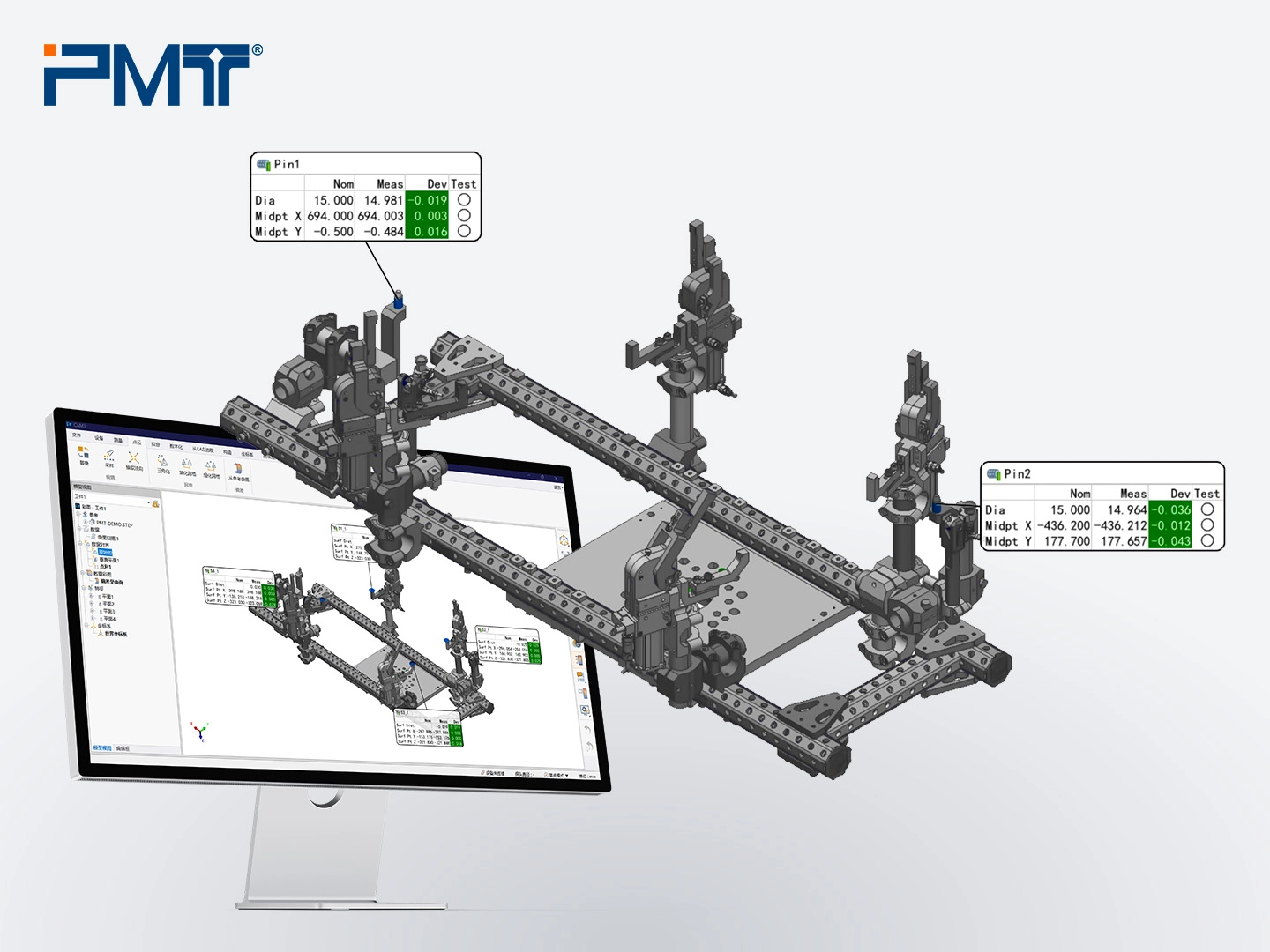

4. Mesurer l'unité de préhension. Les unités de préhension comprennent généralement des goupilles de positionnement cylindriques, des blocs de fixation et des blocs de mandrin. Mesurez les goupilles de positionnement à l'aide de la fonction cylindre et utilisez la fonction Construction/Inspection pour mesurer les blocs de fixation. Les blocs de mandrin sont ajustés par rapport aux blocs et ne nécessitent pas de mesure directe. Comparez toutes les caractéristiques mesurées avec le modèle CAO pour déterminer les ajustements nécessaires.

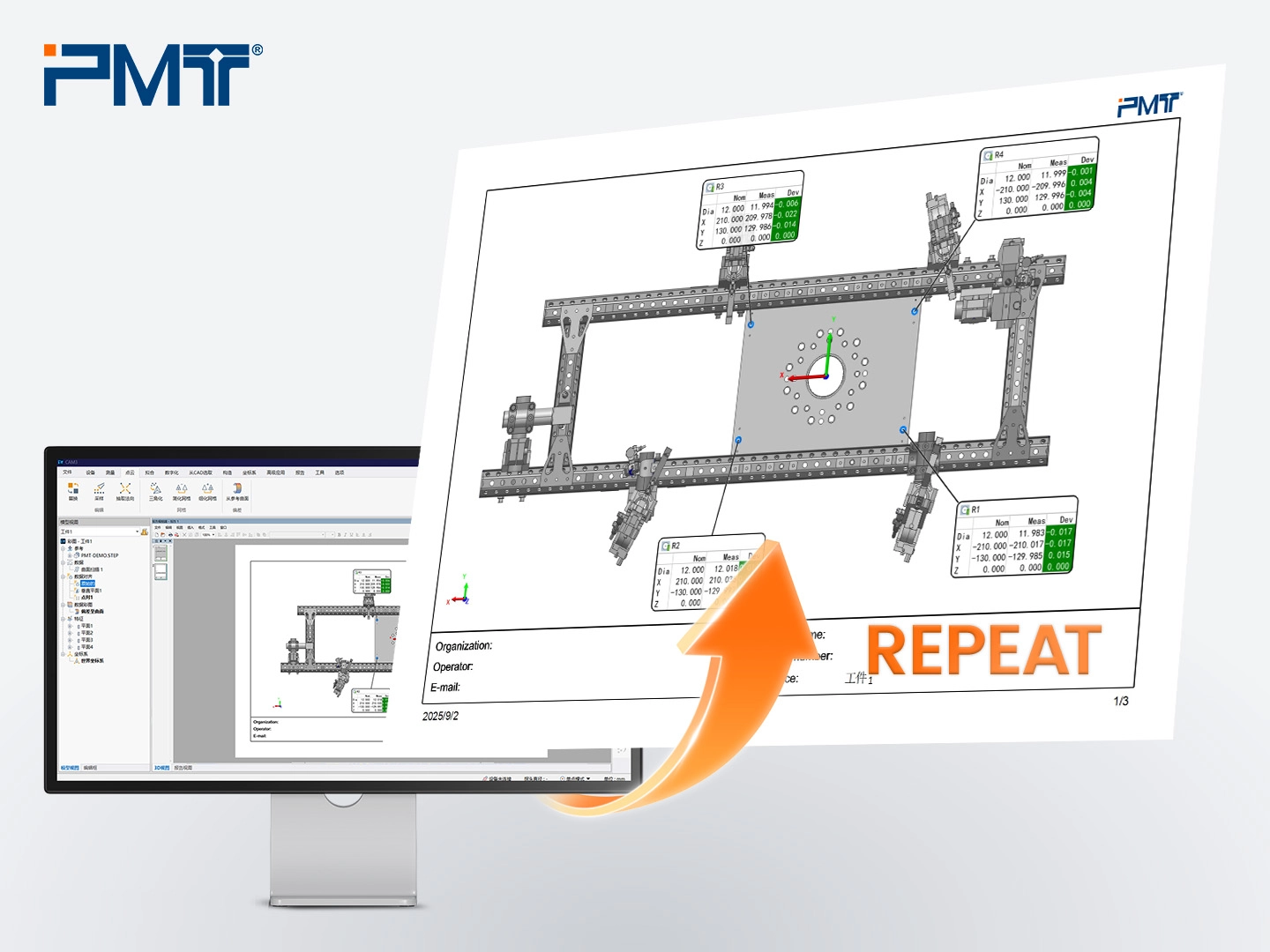

5. Ajustez les modules de préhension en fonction des résultats de la comparaison 3D jusqu'à ce que tous les écarts soient dans les limites de tolérance. Exportez ensuite l'export au format PDF.

Après les premières mesures, la pince octogonale peut encore subir une légère déformation due aux vibrations ou aux forces externes pendant le transport. Il est donc essentiel de la mesurer à nouveau sur site à l'aide d'une MMT portable après l'installation. Cela garantit ses performances et confirme sa précision.

Le processus de nouvelle mesure reflète les contr?les initiaux en usine, ne nécessitant généralement qu'une comparaison 3D pour vérifier la précision de l'unité de préhension.

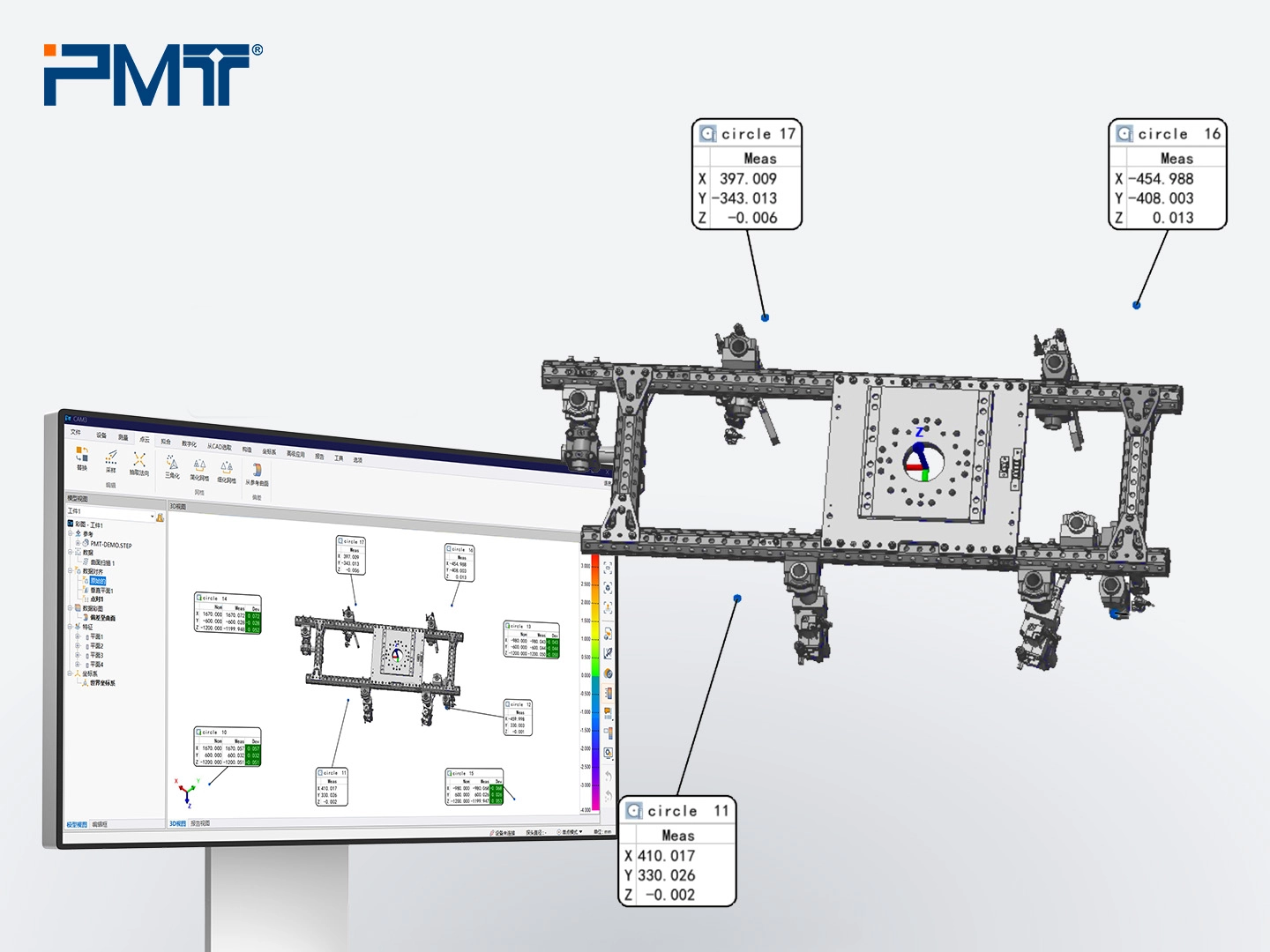

Une fois la précision de la pince confirmée, l'étalonnage du robot peut être effectué sur les dispositifs de soudage. Il faut d'abord établir un système de coordonnées à l'aide du dispositif de la pince et définir la trajectoire du robot. Ensuite, à l'aide d'un bras de mesure portable, mesurer les coordonnées d'au moins quatre trous de référence fixes le long de la trajectoire. Enfin, saisir ces valeurs dans le système du robot pour finaliser l'étalonnage.

Le client turc a expliqué qu'avant d'acheter le bras de mesure portable PMT, il externalisait la plupart des taches de mesure. Cependant, la récente augmentation des commandes, les délais de livraison raccourcis et l'approvisionnement en matériaux externes ont compliqué la planification des mesures, ce qui a entra?né une hausse significative des co?ts de production.

Depuis l'acquisition du bras PMT, ces problèmes ont été résolus. Après seulement deux jours de formation, les installateurs de l'entreprise ont rapidement ma?trisé l'appareil. Le flux de travail intégré a éliminé les erreurs d'installation et réduit considérablement les co?ts liés aux mesures externalisées.

Les pinces à tubes octogonales sont largement utilisées dans les secteurs du soudage et de l'automatisation automobiles en raison de leur conception modulaire, de leur haute résistance, de leur facilité d'assemblage et de leur longue durée de vie. De plus, la machine à mesurer tridimensionnelle portable garantit une haute précision, une portabilité et une inspection 3D rapide, ce qui est essentiel pour vérifier la précision de la pince avant expédition et réduire les délais de livraison tout en réduisant les co?ts. Le bras de mesure est donc devenu un outil indispensable dans le processus de production des pinces à tubes octogonales.